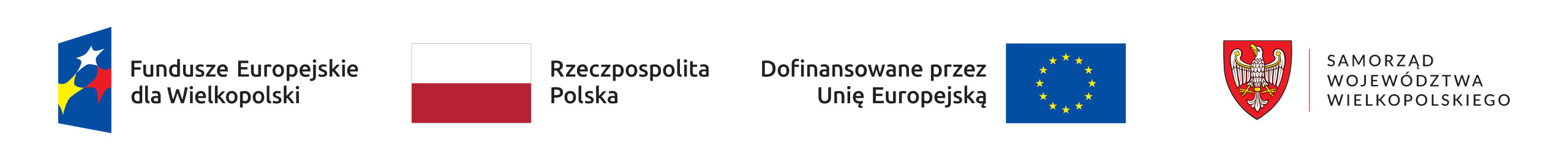

KVT specializes in the purification of glycerin, a by-product of biodiesel production

-

Production of high-margin glycerin with purity ranging from 86.5% to 99.7%, including kosher glycerin, sourced from sustainable plant-based raw materials.

-

Minimal by-products thanks to the integrated MONG desalination unit.

-

Use of widely available raw materials.

The product has a wide range of applications in:

-

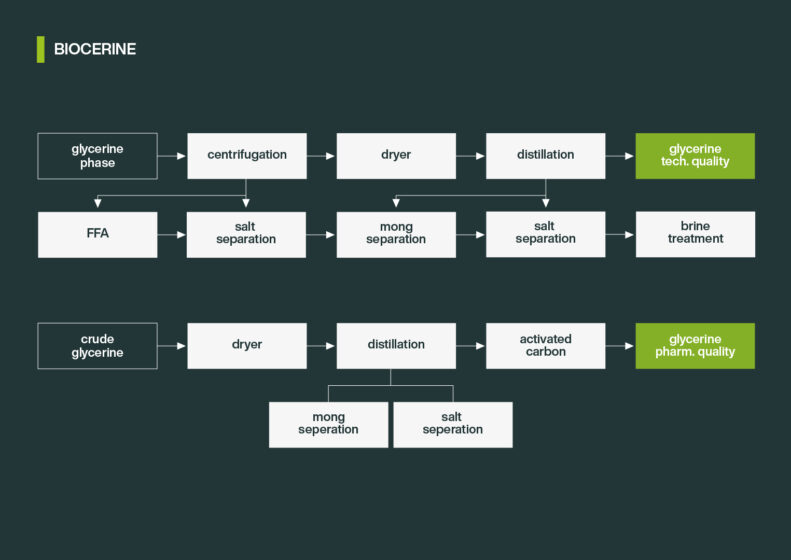

chemical industry

-

pharmaceutical industry

-

cosmetics industry

-

food processing industry

-

detergents industry

-

plastics and lacquer industry